Product

LCD Materials

LCD Materials

Stripper

| - |

For General Process |

| Applications |

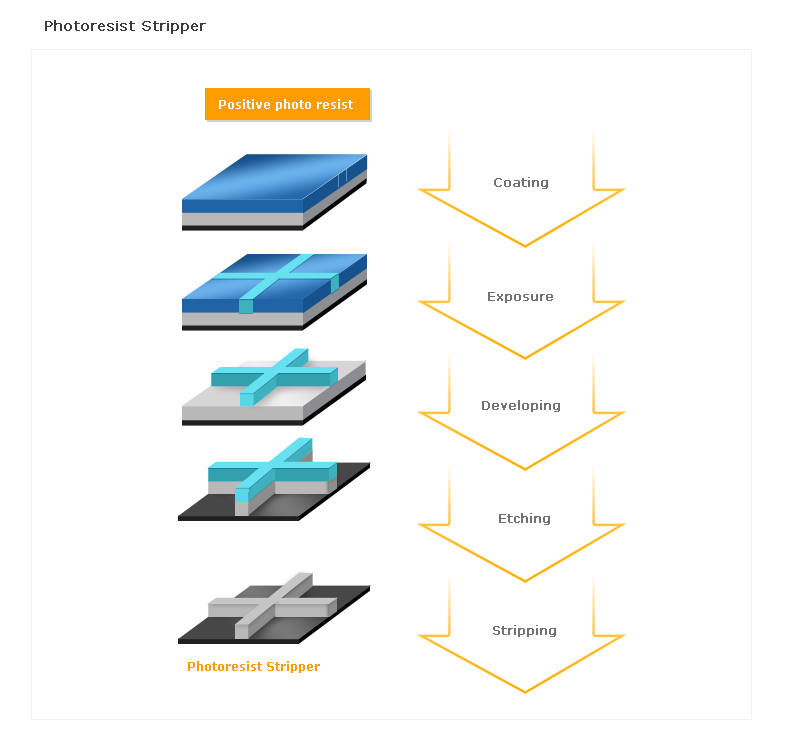

Daxin has developed a stripper that deals specifically with positive photoresists, particularly after under-layered patterns are defined after etching processes have been completed. Since photoresist products require subsequent removal prior to the commencement of further manufacturing processes, strippers need to be formulated to efficiently and effectively remove photoresists, as well as other debris that might interfere with subsequent LCD manufacturing processes, while not corroding or damaging underlying surfaces that need to remain clean and must retain precision levels of flatness and smoothness.

| Features |

- Rapid Photoresist Absorption and Stripping Performance

- Non-Corrosive to Metal Substrates

- Easy Recycling: Reduction of Waste Products and Opportunities for Cost Minimizing

| Specifications |

| Product Name | GD-100 | GD-200 | |

| Solvent Type | BDG | DMSO | |

| Boiling Point | ℃ | 120~145 | 175~200 |

| Processing Temperature | ℃ | 50~85 | 50~85 |

| - | For Cu/Mo Process |

| Applications |

The stripper is used to remove positive photoresist, particularly after patterns of Cu/Mo metal wire are defined after etching process completion, where positive photoresist has the potential to re-adhere to surfaces if it is not properly removed. Additionally, the photoresist chemical must not corrode Cu wiring during this cleaning and removal process.

| Features |

- Non-Corrosive to Cu, Mo, Al, ITO and IGZO Patterns

- Water Compatible, Favorable for Post-Clean Process

- Regenerable and Environmental Friendly

- No By-product Toxicity from Regenerative Chemical Processes

| Specifications |

| Test Item | Unit | GD-series | Remarks |

| Appearance | Colorless to light yellow | ||

| Density | g/cm3 | 1.062~1.082 | |

| pH value | 11 | 30% aq. | |

| Solubility | Soluble in water | ||

| Operating Temp. | ℃ | 40~50 |